The Stahly NL4500G4 EDGE has an option of the MultiBin and MultApplier

The NL4500G4 Edge comes standard with independent spinner speed and edge of field technology. With dual RPM sensors, operators can maintain precise speed on each spinner within 5 RPM. Flip a switch, and operators can apply nutrients along a boundary line, leading to improved nutrient placement, and decreased nutrient waste.

Precision Application

Ease of Use

Ease of Maintenance

Optional Features

Increase productivity by spreading two products in a single pass with the MultApplier, or up to four with the MultiBin. Both inserts allow for the additional products to be spread independently or simultaneously with the main bin, and at straight or variable rates.

| Right Source | Match nutrient and micronutrient type to crop needs with the ability to apply up to four products at once. | |

| Right Rate | Variable rate to match the right amount of nutrients to crop needs. | |

| Right Time | Apply nutrients responsibly at the right time with greater efficiency and productivity. | |

| Right Place | Position nutrients where crops need them while keeping them out of sensitive areas. |

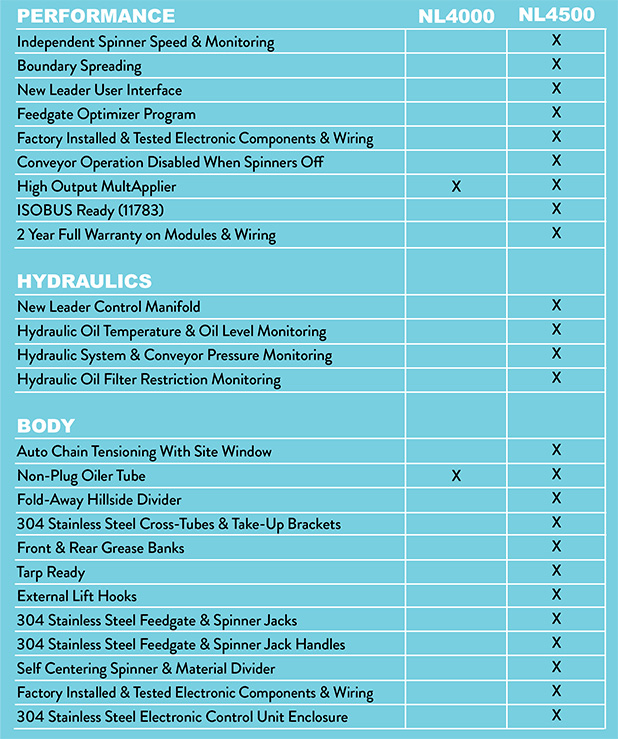

The Stahly NL4500 Edge does not add any moving parts at the rear of the bed. It has individual spinner speed, hydraulic chain tensioners, will do boundary spreading, it is tested by New Leader before it leaves HECO, has New Leader modules instead of Raven nodes and an easy to understand and use New Leader interface which includes the feed gate optimizer.

Precision Application

Spread materials faster, wider and more consistently with patented G4 spinner technology that’s industry proven. Take advantage of dual RPM sensors and pulse width modulation (PWM) valves to maintain precise speed on each individual spinner within 5 RPM. And, give operators the power to apply along a boundary line for the most precise nutrient placement toward maximum yields.

Can I apply more than one product with the Edge?

Increase productivity and reduce operating expenses with the MultApplier to spread two products or the MultiBin to apply up to four products in one pass. Add a 5- or 7-ft MultApplier insert and apply one or two products simultaneously or at variable rates in one pass. With the MultiBin, operators can apply a wider range of micronutrients.

New Leader User Interface: New Leader makes it easy for operators to jump the cab and get to work in the field—and the Edge continues that tradition with plug-and-play ISOBUS electronics that hook into compatible controllers through standardized plugs, cables and software. It also incorporates the power of diagnostic feedback, automatic service notifications, boundary spreading, a feed gate optimizer, low bin countdown and automatic chain oiler. It can be expanded to control multiple bins.

Can I use the Edge on any brand of equipment?

Yes, all Edge models are designed with advanced ISOBUS technology, so the electronics easily connect with any compatible controller. Operators only have to learn one system, cutting down on troubleshooting time. All Edge ISOBUS systems are extensively tested to ensure maximum reliability and performance.

Precision Manufacturing: The best field results only come with the most precisely manufactured equipment—and the Edge delivers. Advanced product techniques like laser cutting and slot-and-tab design create self-centering components such as the material divider and spinner frame. Precision on the back end translates to precision on the front lines, and a machine that maintains a consistent drop point to create repeatable product placement.

Easy Maintenance: The Edge is built with the operator in mind—maximizing time in the cab and the field and simplifying maintenance. A flip-up hillside divider lets operators move easily between spreading lime and other products, while maintaining max flow — and without getting out the toolbox. Front and rear grease banks make machine greasing easy and efficient. Cross tubes, mounts and take-up brackets made of 304 stainless steel provide maximum corrosion resistance on key high-wear components.

Advanced Hydraulics: Experience fast and exact conveyor control, independent spinner speed control and extended conveyor life with the Edge’s superior hydraulics system. High-tech sensors give operators early insights into potential issues by monitoring hydraulic condition and performance based on fluid level, temperature and filter restriction along with conveyor and system pressure. Multiple test ports make in-field service and diagnostics easier.

How does the Edge extend conveyor life?

The Edge maintains proper chain adjustments with an automatic chain tensioner. Continuous tension helps extend life. In addition, operators receive automatic lubrication alerts after 10 hours of conveyor run time.

MultApplier for Dual Product Application

Economics and productivity aren’t exclusive – reduce man hours, field compaction and fuel consumption by applying two products in a single pass with the MultApplier, available in 5 ft or 7 ft sizes.

Is the MultApplier difficult to install? Bolted-in endgates make the MultApplier easy to install or remove, and easy to convert your spreader from single to dual product operation.

Patented Precision Application: Spread materials faster, wider and more consistently, even on windy days, with proven G4 variable rate broadcasting technology. Two independent conveyors allow control of two products at predetermined rates or variable rates, with swath widths up to 84 ft.

MultiBin Fertilizer and Micronutrient Spreader

Transform a single-bin spreader to three or even four bins with the revolutionary MultiBin fertilizer and micronutrient spreader. This innovative design gives operators the power to consistently broadcast materials independently, simultaneously, straight or variable rate. All while covering more acres with less downtime for filling. The possibilities for profitability are endless.

How does the MultiBin work? The front two hoppers dispense fertilizer products, while the rear hopper dispenses micro-nutrients or seeding products. The rear hopper can also be split to create a fourth hopper.

Can the MultiBin be removed once I’ve installed it? The MultiBin can be easily installed and removed from the spreader for single-bin fertilizer or lime spreading.

Why should I apply more than one product at a time? Applying multiple products at once means fewer trips across the field – for reduced soil compaction, labor and fuel consumption.

The NL4500 variable rate dry nutrient applicator utilizes patented G4 spinner technology, proven to spread materials faster, wider, and more consistently. The Edge technology features precise boundary spreading, automatic chain tensioning and New Leader user interface, among other new features. The benefit of the advanced technology of the ISOBUS capabilities means there is a need to learn only one system.

Responsible Nutrient Management includes New Leader. The Edge is the right technology in the right machine from the right company at the right time.