Rugged, Dependable, Simple and Long Lasting

100% 304 Stainless Steel Throughout

Stonger Tanks

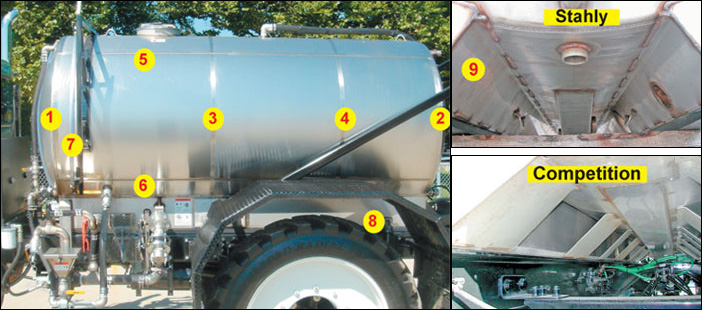

Press formed heads with a #4 polished finish.

Press formed heads with a #4 polished finish.

![]() Two internal baffles provide much more stability. Dished heads are used instead of flat plate for added strength.

Two internal baffles provide much more stability. Dished heads are used instead of flat plate for added strength.

Longitudal welded seams are stronger than one weld around the the center of a tank. Four longitudal seams, five around the circumference and five dished heads provide the durability required for the toughest conditions.

Longitudal welded seams are stronger than one weld around the the center of a tank. Four longitudal seams, five around the circumference and five dished heads provide the durability required for the toughest conditions.

100 gallon internal rinse tank in the front of our tank with fittings for a hand washer or pressure washer. Top sparger provides a complete rinse of all internal surfaces.

100 gallon internal rinse tank in the front of our tank with fittings for a hand washer or pressure washer. Top sparger provides a complete rinse of all internal surfaces.

We specify a 33% thicker 3/16” skid and a one piece continous sill

We specify a 33% thicker 3/16” skid and a one piece continous sill  our tanks hold up in the roughest terrain.

our tanks hold up in the roughest terrain.

The Gas Accumulators, Industrial Hydraulics and Rugged Construction

The Best Boom Tubes in the Industry

Heavy Duty Fold-Over Hinge

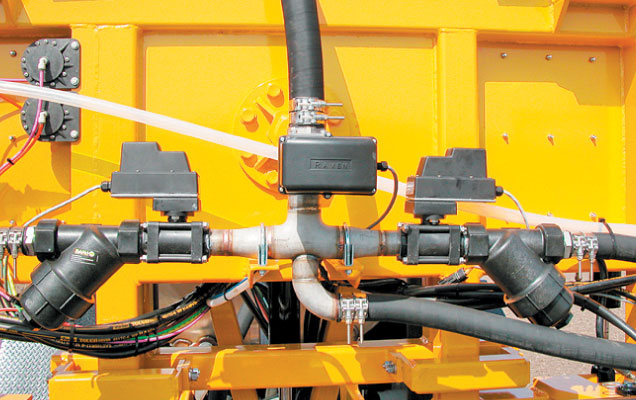

Ease of Service