High output and high capacity come together in the NL345 drawn dry box spinner spreader. For applicators who demand unrelenting performance for spreading ag lime and dry fertilizer, plus a superior return on asset, this machine delivers the flexibility to multi-task tractors for field operations including anhydrous ammonia application, strip-till and side dress application.

Advanced High-Capacity Conveyor System

The NL345 delivers smooth, continuous product flow, plus the durability to stand up to tough fertilizer and lime spreading conditions. And for the heaviest lime spreading, a #4 belt-over-chain conveyor incorporates a multi-ply belt over a heavy-duty pintle chain.

The NL345 consistently applies up to 60 ft. (18 m) spread patterns with ag lime and up to 90 ft. (27 m) for fertilizer.

Precision Application

Spread materials faster, wider and more consistently, even on windy days, with proven G4 variable rate broadcasting technology

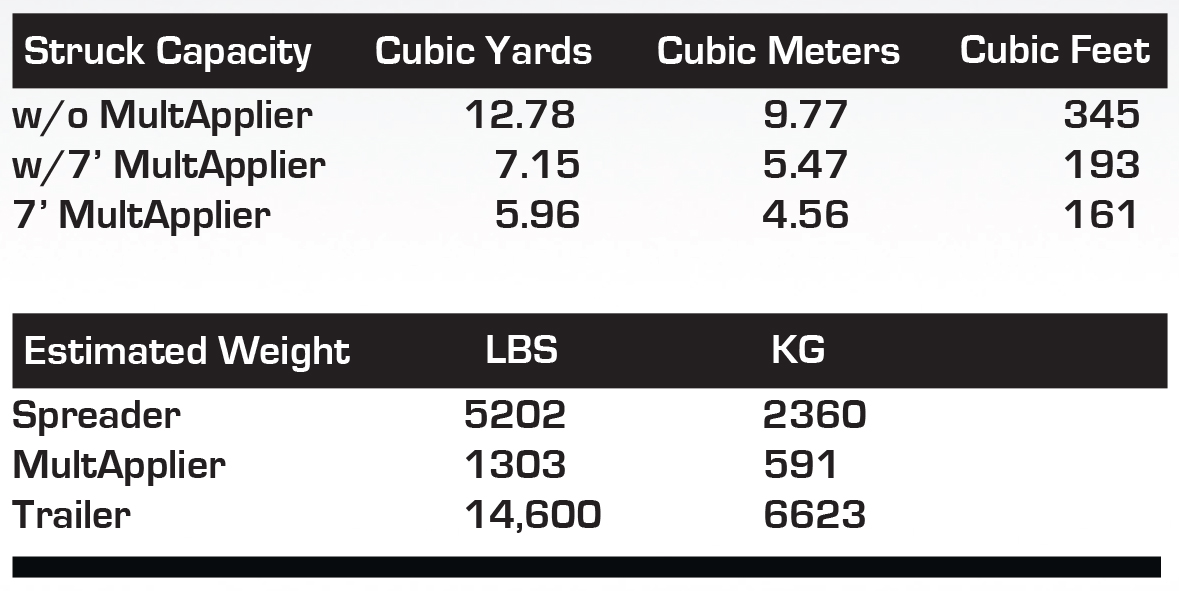

MultApplier Ready

Easily convert from single to dual product spreading with the revolutionary MultApplier. Bolted-in endgates and stainless stainless steel hydraulic connections take this optional component to the next level, and make it easy to add or remove. With the 7 ft. MultApplier installed, the NL345 spreads up to 90 ft. (27 m).

The dual hopper system features two independent conveyors that can simultaneously apply two products at predetermined or variable rates.

Precision Manufacturing

Precision application starts from the ground up – with precision manufacturing. Advanced production techniques like laser cutting deliver advantages like one-piece side sheet construction for fewer seams and potential corrosion zones. Precision on the back end translates to precision on the front lines.